Written by Sean Douglas, National Practice Leader, Hazardous Materials, Pinchin Ltd.

Did this article’s title give you pause? Did it make you wonder: wasn’t asbestos banned and phased out in the 1980’s? What’s this about a 2018 ban? That can’t be right, can it? The saying “better late than never” rings true and the Prohibition of Asbestos and Products Containing Asbestos Regulations (SOR/2018-196) in fact, came into effect on December 30th, 2018.

Now you may be wondering: what does this mean for construction professionals, property managers, owners and developers? To answer this question, we first need to revisit the history of asbestos and how this dangerous material has managed to dodge the government’s phase-out tactics for so long. Having worked in this industry for the best part of 30 years, I’ve been fortunate enough to experience this journey almost since the start. As we near the fourth anniversary of the 2018 Asbestos Prohibition, I believe now is the perfect time to navigate this journey again and educate industry stakeholders on our asbestos status.

The History of Asbestos

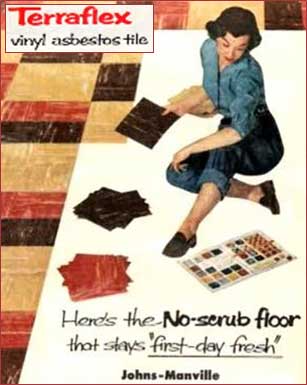

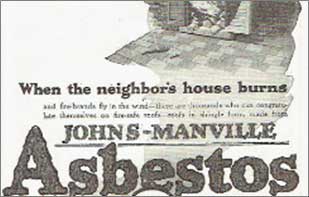

Asbestos is a group of naturally occurring minerals made up of very thin fibres, which rose to prominence in the early 1900’s when industry learned of its heat resistance, tensile strength and insulating qualities, and it was quickly popularized in construction and commercial sectors. It was during the post war period (1945-1970) when asbestos use peaked in North America with over 3,000 documented asbestos products being manufactured.

Health Risks

It wasn’t until the early 1970’s that the negative health impacts of long-term asbestos exposure were fully published and disclosed by the manufacturers, and governments were left scrambling to draft legislation for a material they didn’t yet fully understand. Their task was made even more challenging by the fact that asbestos was already in use and installed in many homes, buildings and structures.

The health risks due to asbestos exposure is clearly linked, occurring when airborne asbestos fibres are inhaled and are trapped within the lungs and respiratory system. However, symptoms do not usually appear due to a long latency period of 20-35 years. Occupational deaths from mesothelioma, a rare respiratory cancer caused almost exclusively from asbestos exposure, increased 60 percent between 2000 and 2012, according to Statistics Canada. Experts estimate 150,000 Canadians are exposed to asbestos at work, particularly in the construction industry.

A Natural Resource in Canada

Another problem the Canadian government faced was that asbestos was profitable and in abundance. Canada has always been a resource-based economy, and voters were reluctant to elect officials that would take away their source of income. The last asbestos mine wasn’t closed until 2012 (in Quebec), more than two decades after the 1980’s-era phase-out of common asbestos products and utilizations. During the last few years of asbestos mining in Canada, over 90% of the raw asbestos material was exported to India. To add to this, in 2015, Canada was importing $8.2 million of products that contained asbestos, mainly in brake pads, but other miscellaneous products such as gaskets and cement pipes. Asbestos was completely banned in more than 50 countries by 2016, but Canada’s true ban did not pass until the 2018 Asbestos Prohibition because of these conflicting interests.

Prohibition in Canada

The 2018 Asbestos Prohibition passed regulations prohibiting the import, sale, and use of asbestos as well as the manufacture, import, sale, and use of asbestos-containing products, with a limited number of exclusions (military, nuclear industry and chlor-alkali facilities). Exports are also prohibited, and these regulations effectively prevent new asbestos and asbestos-containing products from entering the Canadian market. While this is great news for Canadians, the Prohibition does not solve the existing problems we are currently facing.

Products Containing Asbestos

There is a common misconception that any building constructed after 1990 will not have asbestos-containing materials (ACMs). While it is true that friable materials (a material that can be crumbled by hand pressure) with large concentrations of asbestos are virtually non-existent in post-1990 builds, we must remember again that over 3,000 different manufactured products containing the material have been in use since before the prohibition went into effect.

In our experience, products that can contain asbestos that were used beyond 1990 and even into the 2000’s, including certain types of sealants, adhesives, mastics, caulking and cement pipes and boards. These products can be found in sealants on window glazing, caulking around door and window frames, caulking on flashings, adhesives, mastics in roof applications, caulking for firestopping and rain water leaders.

Sealant

Butyl Sealant

Gasket

Cement Pipe

Duct Mastic

The good news is that these products typically have low concentrations of asbestos (1-5%) and are non-friable; therefore, inherently less dangerous than friable products. If left undisturbed, non-friable materials such as those described above would typically not present a risk of asbestos exposure during the normal maintenance and occupancy of buildings, however the risk of exposure increases if the material is disturbed by renovation or demolition activity.

Regulations in Canada

In BC, health and safety regulations require an asbestos inventory of the workplace, particularly in advance of renovation or demolition work. If asbestos is identified and could potentially be disturbed, appropriate controls and safe work procedures will be required. Other hazardous materials (e.g. lead-paint, mercury, silica, mould and PCBs) are also required to be identified prior to renovation or demolition activities.

Every element (roof, wall, floor, structure, HVAC, plumbing, finishes) or space within a building can potentially contain asbestos, and there is no way to determine the presence of asbestos without laboratory analysis. This is an intimidating situation for even the experienced construction professional or building owner, which is why Pinchin Ltd. has spent almost 40 years perfecting the hazardous building materials identification and removal process; from sample collection and analysis, design and specifications, through to complete abatement, air monitoring and sign-off. We have the knowledge, resources, and industry understanding to safely and affordably carry out an asbestos and hazardous materials removal program.

Asbestos Training

This is a lot of information to take in, and I’ve only just scratched the surface of this important environmental health and safety issue. If you’re interested in learning more, or if you may encounter asbestos in the workplace or home, you should consider registering to one of Pinchin’s asbestos awareness courses that offer a thorough and concise overview of asbestos uses, health hazards and regulatory requirements. Check out our course calendar here.

If you have any further inquiries, please feel free to reach out to me at 604.244.8101 or sdouglas@pinchin.com. You can also reach out to one of our experienced staff at your local Pinchin office.

Sean Douglas is Pinchin Ltd.’s National Practice Leader for Hazardous Building Materials management. He possesses more than 30 years of experience overseeing this core service group and is well versed in hazardous materials assessment, inventory, abatement specifications, and remediation.